- Work

-

Products

- Products Overview

- TARC Single Lock Standing Seam Roofing

- TARC Double Lock Standing Seam Roofing

- TARC Batten Seam

- TARC Snap Lock Tray Roofing

- TARC Batten Cap Roofing

- TARC Single Lock Standing Seam Cladding

- TARC Snap Lock Tray Cladding

- TARC Double Lock Standing Seam Cladding

- TARC V25 Cladding

- TARC Pe2 Cladding

- TARC Flatlock Cladding

- Custom Folding and Supply Only Roofing & Cladding Products

- TARC Batten Seam

- TARC Batten Cap Cladding

- TARC Corrugate Roofing

- TARC 5-Rib Roofing

- TARC Corrugate Cladding

- TARC 5-Rib Cladding

- Materials

-

Projects

- Projects Overview

- The White Caps House

- Fitness with Finesse

- Milton St Townhouses

- On the Rise

- Richmond Club

- Aldersgate Centre

- Clyde Rd House

- Redcliffs House

- Town Hall

- Wairarapa House

- Geraldine Street Development

- On the Wairarapa banks

- Worsley Spur

- The Copper Curve

- Wairarapa Terrace

- PGG Wrightson - Lincoln

- New Regent Street

- The Shark House

- Manchester Street Townhouses

- Major Hornbrook

- Te Manawa Atawhai Catherine McAuley Center

- The Piano

- PWC Building

- Te Kai - ARA Institute of Technology

- Peterborough Street

- The Hills

- The Papanui Club

- Hillside House

- Salisbury Townhouses

- Supply Only

- About

- Contact

- Careers

- Downloads

Products

From the crafting of premium materials into almost anything you can dream up, to cost-effective long run solutions; our products are tailored to the specific design requirements of each project.

Our roofing range includes flat tray roof that incorporate traditional hand seaming techniques along with long run roofing profiles, while our cladding offers superior flat panel cladding and façade systems.

We can create bespoke items such as curved fascias, feature doors, chimneys, louvres and internal paneling for high-quality points of difference. Everything we produce is either made from the premium copper, zinc, aluminium and steel we source and manufacture using state-of-the-art European CNC technology. We also supply quality European prefabricated products.

Please select a product range:

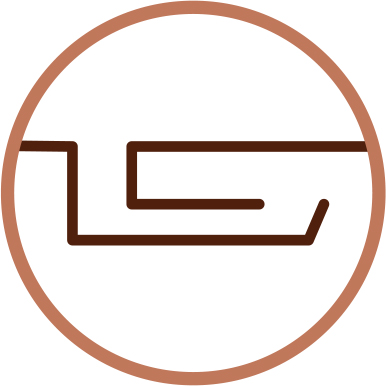

TARC Single Lock Standing Seam Roofing

The taut and regular appearance of this profile emphasises the seam. It has a broader effect than the double-lock system, giving large surface areas a dynamic, striking appearance. Sharp lines, depth and shading make it especially suitable for cladding, and the visible areas of steep roofs.

MATERIAL AND FINISHED OPTIONS

Discover our wide range of options in:

- Copper

- Zinc

- Aluminium

- Steel

Technical specifications

Available in

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55mm | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12 |

| Seam height | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm |

| Panel width | 305-600mm Standard width 515mm |

305-555mm Standard width 515mm |

305-600mm Standard width 505mm and 405mm |

305-600mm Standard width 505mm and 405mm |

| Directions | Vertical/Horizontal | Vertical/Horizontal | Vertical/Horizontal | Vertical/Horizontal |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

System build up

| Roof structure | Must consist of continuous trusses or top hats at max. 600mm spacing. |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed and sliding TARC approved Single Lock brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel |

Fully designed build up system

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Single Lock is available in materials and colours as above |

| Manufacture | All components of the TARC Single Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Double Lock Standing Seam Roofing

Suitable for low-pitched roofs down to 3 degrees, this is an ideal profile for harsh climates where snowfall, strong winds and heavy rains are a consideration. Allows straight or curved, radial or arched design flexibility. High upstand provides elegant depth and shading. It is uniquely designed to account for thermal movement.

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.7mm or 0.8mm | 0.7mm | 0.6mm |

| Panel length | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12 |

| Seam height | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm |

| Panel width | 305-555mm Standard width 515mm |

305-600mm Standard width 505mm and 405mm. |

305-600mm Standard width 505mm and 405mm |

| Directions | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed and sliding TARC approved Single Lock brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Single Lock is available in materials and colours as above |

| Manufacture | All components of the TARC Single Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

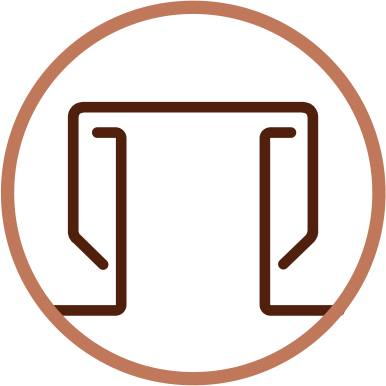

TARC Batten Seam

Similar to the TARC Batten Cap but with a hand-seamed finish, the dramatic lines of TARC Batten Seam produce depth and shading, but with a significantly more open, handcrafted appearance. TARC Batten Seam is ideal for concave or convex roof structures. Both cap profiles can be used in combination with the standing seam for greater variation.

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55 | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12m |

| Seam height | 38mm | 38mm | 38mm | 38mm |

| Panel width | 305-535mm Standard width 535mm |

305-535mm Standard width 425mm and 535mm |

305-600mm Standard width 430mm and 535mm |

305-606mm Standard width 535mm and 606mm |

| Directions | Vertical | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed TARC Batten Seam brackets at max. 400mm centres. Clips to be min. 0.5mm stainless steel or 0.7mm galvanised steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Batten Seam is available in materials and colours as above |

| Manufacture | All components of the TARC Batten Seam system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

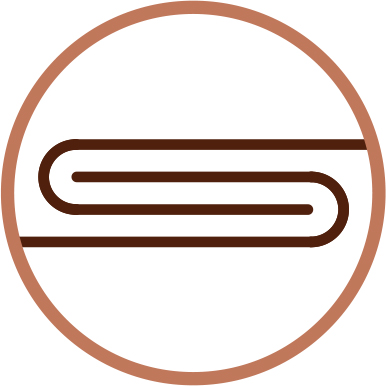

TARC Snap Lock Tray Roofing

This versatile profile adds interest, shadow and depth together with beautiful soft lines. It can be used with either a plywood backing or open purlin applications. Reduced structural requirements and reduced installation times make this system a more cost effective profile.

FEATURES & BENEFITS

- No solid sarking needed

- Details and design solution are comparable to TARC Single Lock

- Cost effective installation with fully concealed brackets

MATERIAL OPTIONS

Discover our wide range of colour options:

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel |

| Thickness | 0.55 |

| Panel length | Please consult us at design stage >15m |

| Seam height | 38mm |

| Panel width | 305-600mm Standard width 460mm |

| Directions | Vertical |

| Minimum Pitch | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Substructure | Must consist of continuous purlins or castelated cavity battens at max. 450mm spacing |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | TARC Snap Lock brackets at 450mm centres. Clips to be min. 0.4mm stainless steel |

FULLY DESIGNED BUILD UP SYSTEM

Roofing system including underlay, metal trays and fixings. Complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials |

TARC Snap Lock is available in pre-painted steel with colours as above |

| Manufacture | All components of the TARC Snap Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

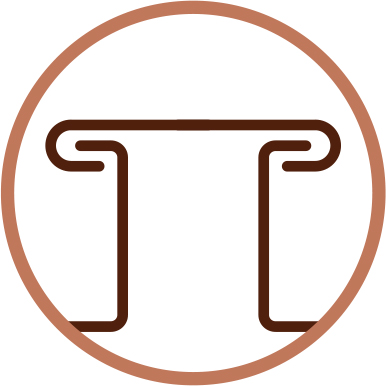

TARC Batten Cap Roofing

Bold contours give this profile its unique urban character. Its structured, longitudinal joints create light and shade variations as the angle of light changes. Easily dismantled for any roof penetrations, maintenance or repair.

FEATURES & BENEFITS

- Incredible flexibility and versatility with TARC Batten Cap metal roofing

- Unlimited design options with panel widths changeable to suit roof width and skylight penetrations; tapered. curved, convex and concave; crossjoints to create specific lines or continuous cladding for long panel applications

- Fully waterproof with all details and panel connections made to leverage inherent material waterproofing

- Economical due to minimal wastage of materials

MATERIAL OPTIONS

Discover our wide range of options in:

- Copper

- Zinc

- Aluminium

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55 | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12m |

| Seam heigth | 38mm | 38mm | 38mm | 38mm |

| Panel width | 305-535mm Standard width 535mm |

305-535mm Standard width 425mm and 535mm |

305-600mm Standard width 430mm and 535mm |

305-606mm Standard width 535mm and 606mm |

| Directions | Vertical | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fix TARC batten cap brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel or 0.7mm galvanised steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | Battencap is available in materials and colours as above |

| Manufacture | All components of the TARC Batten Cap system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Single Lock Standing Seam Cladding

The taut and regular appearance of this profile emphasises the seam. It has a broader effect than the double-lock system, giving large surface areas a dynamic, striking appearance. Sharp lines, depth and shading make it especially suitable for cladding, and the visible areas of steep roofs.

MATERIAL AND FINISHED OPTIONS

Discover our wide range of options in:

- Copper

- Zinc

- Aluminium

- Steel

Technical specifications

Available in

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55mm | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12 |

| Seam height | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm |

| Panel width | 305-600mm Standard width 515mm |

305-555mm Standard width 515mm |

305-600mm Standard width 505mm and 405mm |

305-600mm Standard width 505mm and 405mm |

| Directions | Vertical/Horizontal | Vertical/Horizontal | Vertical/Horizontal | Vertical/Horizontal |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

System build up

| Roof structure | Must consist of continuous trusses or top hats at max. 600mm spacing. |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed and sliding TARC approved Single Lock brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel |

Fully designed build up system

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Single Lock is available in materials and colours as above |

| Manufacture | All components of the TARC Single Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Snap Lock Tray Cladding

This versatile profile adds interest, shadow and depth together with beautiful soft lines. It can be used with either a plywood backing or open purlin applications. Reduced structural requirements and reduced installation times make this system a more cost effective profile.

FEATURES & BENEFITS

- No solid sarking needed

- Details and design solution are comparable to TARC Single Lock

- Cost effective installation with fully concealed brackets

MATERIAL OPTIONS

Discover our wide range of colour options:

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel |

| Thickness | 0.55 |

| Panel length | Please consult us at design stage >15m |

| Seam height | 38mm |

| Panel width | 305-600mm Standard width 460mm |

| Directions | Vertical |

| Minimum Pitch | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Substructure | Must consist of continuous purlins or castelated cavity battens at max. 450mm spacing |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | TARC Snap Lock brackets at 450mm centres. Clips to be min. 0.4mm stainless steel |

FULLY DESIGNED BUILD UP SYSTEM

Roofing system including underlay, metal trays and fixings. Complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials |

TARC Snap Lock is available in pre-painted steel with colours as above |

| Manufacture | All components of the TARC Snap Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Double Lock Standing Seam Cladding

Suitable for low-pitched roofs down to 3 degrees, this is an ideal profile for harsh climates where snowfall, strong winds and heavy rains are a consideration. Allows straight or curved, radial or arched design flexibility. High upstand provides elegant depth and shading. It is uniquely designed to account for thermal movement.

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.7mm or 0.8mm | 0.7mm | 0.6mm |

| Panel length | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12 |

| Seam height | 25mm / 38mm | 25mm / 38mm | 25mm / 38mm |

| Panel width | 305-555mm Standard width 515mm |

305-600mm Standard width 505mm and 405mm. |

305-600mm Standard width 505mm and 405mm |

| Directions | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed and sliding TARC approved Single Lock brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Single Lock is available in materials and colours as above |

| Manufacture | All components of the TARC Single Lock system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC V25 Cladding

Interlocking TARC V25 panel allows for a range of axel dimensions when designing facades. Panels can be installed horizontally, vertically or diagonally.

FEATURES & BENEFITS

- Interlocking attachment with concealed fastening

- In conjunction with an metal substructure a non flammable build up is possible

- Versitale self supporting cladding system for non-ferrous metals

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Aluminium coil-coated | Zinc | Copper |

| Thickness | 1mm | 1mm | 1mm |

| Panel length | max. 4000mm | max. 4000mm | max. 4000mm |

| Cassette depth | 25mm | 25mm | 25mm |

| Panel width | 100-300mm Standard width 250mm and 300mm |

100-300mm Standard width 250mm and 300mm |

100-300mm Standard width 250mm and 300mm |

| Directions | Vertical/Horizontal | Vertical/Horizontal | Vertical/Horizontal |

| Negative detail | 8-20mm | 8-20mm | 8-20mm |

SYSTEM BUILD UP

| Substructure | Must consist of continuous timber cavity battens or TARC aluminium top hats at max. 600mm spacing perpendicular to the Panel direction. The substructure layout has to be developed to suit the specific demands of the project |

| Cavity | Drained and vented, minimum 20mm |

| Underlay | For not vertical walls (60 - 90 degrees) a fully waterproof membrane has to be installed behind the cavity |

| Fixings | Self tapping stainless steel 18/8 screws Type SFS SN3/11 S 7504/K 4.8x19 or similar to fixed into TARC top hats Self tapping stainless steel screws hex washer head screw 12Gx35mm to fix to timber battens |

FULLY DESIGNED BUILD UP SYSTEM

Rain screen wall cladding system including top hats, battens, metal panels and fixings, complete with all flashings, trims and details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC V25 Interlocking panel is available in materials and colours as above |

| Manufacture | All components of the TARC V25 Interlocking system are manufactured project specifically by TARC in one of our manufacturing facilities |

TARC Pe2 Cladding

TARC Pe2 achieves complex architectural elements such as curves, arcs, edges or overhanging ceilings. Its flexibility adapts to design ideas, giving architects and designers the freedom to create a tailored rain screen.

FEATURES & BENEFITS

- Unlimited design options with panel sizes customizable to suit wall penetrations; tapered panels, crossjoints to create specific lines and a large range of powder coat finishes

- In conjunction with an metal substructure a non flammable build up is possible

- Small environmental footprint due to minimal wastage of materials, local manufacturing and powder coating

MATERIAL OPTIONS

Discover our wide range of colour and finish options in:

- Aluminium coil-coated

- Aluminium powder-coated

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Aluminium 5005 H34 |

| Thickness | 2mm |

| Panel length | max. 3540mm |

| Cassette depth | 28mm |

| Panel width | 100-700mm |

| Directions | Vertical/Horizontal |

| Negative detail | 15-35mm |

SYSTEM BUILD UP

| Substructure | Consists of continuous timber cavity battens or TARC aluminium top hats at max. 600mm spacing perpendicular to the panel direction. The substructure layout has to be developed to suit the specific demands of the project |

| Cavity | Drained and vented, minimum 20mm |

| Underlay | Synthetic underlay, if installed to timber substructure |

| Fixings | Proprietary extruded aluminium bracket for hidden fixing to substructure |

FULLY DESIGNED BUILD UP SYSTEM

Rain screen wall cladding system including TARC top hats or timber battens, Pe2 panels and fixings, complete with all flashings, trims and details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Pe2 panel is available in 2mm aluminium, colours and finishes as above |

| Manufacture | All components of the TARC Pe2 panel system are manufactured project specifically by TARC in one of our manufacturing facilities |

TARC Flatlock Cladding

Aesthetically impressive, the TARC Flatlock excels in large format facades. Panels can be fabricated in varying sizes to suit individual requirements and can be laid vertically or horizontally. A “stretcher bond” appearance can be created in either symmetrical or random patterns.

FEATURES & BENEFITS

- Unlimited design options to structure large facades with small format metal cladding

- Well suited to complex facades featuring curves, both convex and concave

- A large variation of pre-manufactured panel types and sizes or custom made panels are available

- Different join appearances are possible, all featuring a concealed bracket

- Non-combustable build up is available

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Aluminium coil-coated | Zinc | Copper |

| Thickness | min 0.7mm | min 0.7mm | min 0.7mm |

| Panel length | max. 4000mm | max. 4000mm | max. 4000mm |

| Panel width | 100-350mm | 100-350mm | 100-350mm |

| Directions | Vertical/Horizontal/Diagonal | Vertical/Horizontal/Diagonal | Vertical/Horizontal/Diagonal |

| Pre-Manufactured panels available | Prefa |

SYSTEM BUILD UP

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Cavity | Minimum 20mm |

| Underlay | Fully breathable and waterproof synthetic underlay |

| Fixings | TARC approved Flatlock brackets. Clips to be min. 0.4mm stainless steel and maximum spacing at 350mm in every direction |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported cladding system including sarking, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Flatlock cladding is available in materials and colours as above |

| Manufacture |

All components of the TARC Flatlock system are manufactured specifically by TARC in our manufacturing facility For pre-made Flatlock panels all complementary components necessary, will be manufactured by TARC |

Custom Folding and Supply Only Roofing & Cladding Products

Custom Folding

With our state-of-the-art CNC technology from Europe and Australia we can create most flashings or custom designs

With custom designs at the forefront of our business we are now offering supply only folding facilities. Do you have a flashing you need made but don't know where to take it? Do you have project that requires something out of the ordinary?

We can now fold up to 8m long with our newest addition folder.

We can provide material or this can be provided by you.

Give us a call or drop in to discuss your needs.

TARC Batten Seam

Similar to the TARC Batten Cap but with a hand-seamed finish, the dramatic lines of TARC Batten Seam produce depth and shading, but with a significantly more open, handcrafted appearance. TARC Batten Seam is ideal for concave or convex roof structures. Both cap profiles can be used in combination with the standing seam for greater variation.

MATERIAL OPTIONS

Discover our wide range of material and finish options in:

- Copper

- Zinc

- Aluminium

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55 | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12m |

| Seam height | 38mm | 38mm | 38mm | 38mm |

| Panel width | 305-535mm Standard width 535mm |

305-535mm Standard width 425mm and 535mm |

305-600mm Standard width 430mm and 535mm |

305-606mm Standard width 535mm and 606mm |

| Directions | Vertical | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fixed TARC Batten Seam brackets at max. 400mm centres. Clips to be min. 0.5mm stainless steel or 0.7mm galvanised steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 10 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Batten Seam is available in materials and colours as above |

| Manufacture | All components of the TARC Batten Seam system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Batten Cap Cladding

Bold contours give this profile its unique urban character. Its structured, longitudinal joints create light and shade variations as the angle of light changes. Easily dismantled for any roof penetrations, maintenance or repair.

FEATURES & BENEFITS

- Incredible flexibility and versatility with TARC Batten Cap metal claddinh

- Unlimited design options with panel widths changeable to suit roof width and skylight penetrations; tapered. curved, convex and concave; crossjoints to create specific lines or continuous cladding for long panel applications

- Fully waterproof with all details and panel connections made to leverage inherent material waterproofing

- Economical due to minimal wastage of materials

MATERIAL OPTIONS

Discover our wide range of options in:

- Copper

- Zinc

- Aluminium

- Steel

TECHNICAL SPECIFICATIONS

AVAILABLE IN

| Material | Pre-painted Steel | Aluminium coil-coated | Zinc | Copper |

| Thickness | 0.55 | 0.7mm or 0.8mm | 0.7mm | 0.7mm |

| Panel length | Please consult us at design stage >15m | Please consult us at design stage >10m | Please consult us at design stage >10m | Please consult us at design stage >12m |

| Seam heigth | 38mm | 38mm | 38mm | 38mm |

| Panel width | 305-535mm Standard width 535mm |

305-535mm Standard width 425mm and 535mm |

305-600mm Standard width 430mm and 535mm |

305-606mm Standard width 535mm and 606mm |

| Directions | Vertical | Vertical | Vertical | Vertical |

| Minimum Pitch | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* | 3.0 degrees* |

* Pitch < 7 degrees is subject to location and design, please contact us for further information.

SYSTEM BUILD UP

| Roof structure | Must consist of continuous trussers or top hats at max. 600mm spacing |

| Direct support |

Standard - Plywood 15mm structural to AS/NZS 2269 Non-flammable - MgO board min. 15mm |

| Underlay | Fully breathable and waterproofed underlay |

| Fixings | Fix TARC batten cap brackets at max. 400mm centres. Clips to be min. 0.4mm stainless steel or 0.7mm galvanised steel |

FULLY DESIGNED BUILD UP SYSTEM

Fully supported roofing system including plywood, membrane, metal and fixings, complete with all flashings, trims and waterproofed details meeting adjoining building materials.

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | Battencap is available in materials and colours as above |

| Manufacture | All components of the TARC Batten Cap system are manufactured by TARC in one of our manufacturing facilities. Trays over 8m length are typically roll-formed on site |

TARC Corrugate Roofing

Technical specifications

Available in

| Material | Pre-painted Steel |

| Thickness | 0.55mm or 0.40mm |

| Panel length | Please consult us at design stage >15m |

| Panel width | 853mm, Cover 768mm |

| Directions | Vertical |

| Minimum Pitch | 8.0 degrees |

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Corrugate is available in materials and colours as above |

| Manufacture | TARC Corrugate is manufactured by TARC in our manufacturing facility here in Christchurch. |

TARC 5-Rib Roofing

Technical specifications

Available in

| Material | Pre-painted Steel |

| Thickness | 0.55mm or 0.40mm |

| Panel length | Please consult us at design stage >15m |

| Panel width | 830mm, Cover 770mm |

| Directions | Vertical |

| Minimum Pitch | 3.0 degrees |

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship |

| Materials | TARC 5-Rib is available in materials and colours as above |

| Manufacture | TARC 5-Rib is manufactured by TARC in our manufacturing facility here in Christchurch. |

TARC Corrugate Cladding

Technical specifications

Available in

| Material | Pre-painted Steel |

| Thickness | 0.55mm or 0.40mm |

| Panel length | Please consult us at design stage >15m |

| Panel width | 853mm, Cover 768mm |

| Directions | Vertical, Horizontal |

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship Extended warranties available on request |

| Materials | TARC Corrugate is available in materials and colours as above |

| Manufacture | TARC Corrugate is manufactured by TARC in our manufacturing facility here in Christchurch. |

TARC 5-Rib Cladding

Technical specifications

Available in

| Material | Pre-painted Steel |

| Thickness | 0.55mm or 0.40mm |

| Panel length | Please consult us at design stage >15m |

| Panel width | 830mm, Cover 770mm |

| Directions | Vertical |

| Minimum Pitch | 3.0 degrees |

| Warranty |

Min. 15 years warranty covering material, min. 5 years on workmanship |

| Materials | TARC 5-Rib is available in materials and colours as above |

| Manufacture | TARC 5-Rib is manufactured by TARC in our manufacturing facility here in Christchurch. |